Sack & Kiesselbach at the World Money Fair

by Ursula Kampmann, translated by Maike Meßmann

Those who set foot into the World Money Fair’s technical hall, where suppliers present themselves, can hardly imagine how much logistics is involved in creating the splendid booths. Several exhibitors even set up incredibly heavy machines. Sack & Kiesselbach, for example, present one of their many minting presses at the fair every year.

Content

While traditional coin dealers load some coin trays into a normal mid-range car, transporting a minting press such as the MPP-250 requires a lot of time and effort. Why does a highly successful company such as Sack & Kiesselbach even bother to do so?

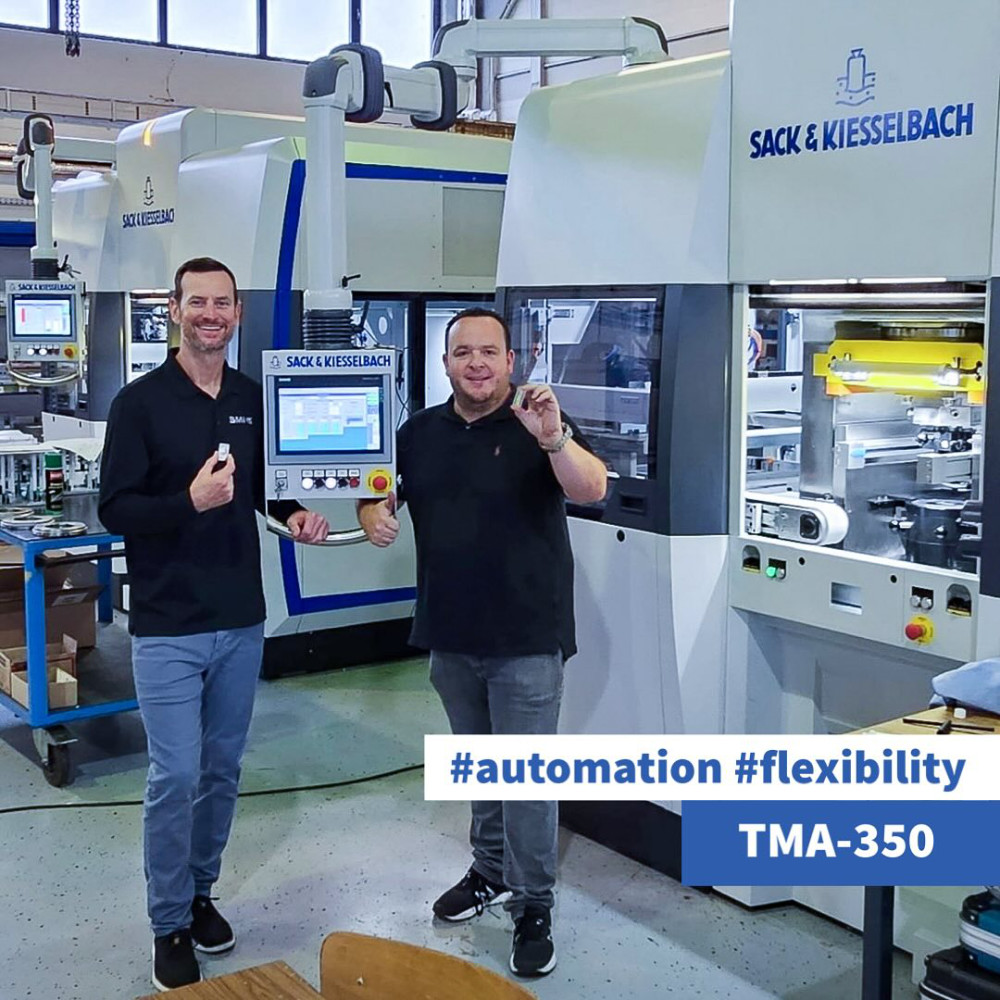

Markus Schlein (r.) and Jason Trubey of the Sunshine Mint (l.) in front of a TMA-350; TMA is short for Table Medal Automat, a compact press with standard direct servo drive. Image: Sack & Kiesselbach.

An MPP-250 for the World Money Fair

Markus Schlein explains: “To us, the World Money Fair is one of the most important events in the coin world. We want our booth to attract as many people as possible. That’s why we already start thinking about how to present ourselves months before the World Money Fair begins. This time, we focused on our MPP-250. If you are not familiar with our products: MPP-250 is short for a Manual Production Press with a pressing force of up to 250 tons. The oil-hydraulic servo press is one of our smallest, highly flexible and most efficient presses. Therefore, it is of particular interest to all those who want to mint issues of small mintage figures in quick succession. As I said, the big advantage is that the MPP is incredible flexible, rather small and therefore easy to handle. That is exactly what we wanted to demonstrate at the World Money Fair. Therefore, we did not set up a new MPP-250 in the hall but went to one of our customers to present an MPP-250 that is currently in operation. We loaded it into a truck on Wednesday morning in Veitsrodt close to Idar-Oberstein, transported it to Berlin, set it up on Thursday, used it for minting purposes during the fair and took it back on the Monday after the fair. On Tuesday, it was back in operation in Veitsrodt. We documented the trip on our social media channels. We wanted to demonstrate how flexible the machine can be used. We would like to thank the company Joly GmbH, as they allowed us to take the machine for almost a week despite their tight production schedule. They only did it because they know exactly that they can have the machine back in normal operation after six days.”

Everyone Minted Their Own Medal

The Joly GmbH in Veitsrodt, where Sack & Kiesselbach took the press from, is one of many private companies that produce commemorative coins and bullion products of very small mintage figures. That is why the MPP-250 was an ideal choice for Joly GmbH. It is the same for many other companies that exclusively produce commemorative coins and medals for the booming market.

The activity Markus Schlein had planned for the WMF required such a very machine. He wanted to enable visitors to mint coins themselves on a modern minting machine. Markus Schlein explains: “The World Money Fair launched the World Money Fair Club this year. A great idea. I joined immediately. Prior to the fair, the new CEO of the World Money Fair Goetz-Ulf Jungmichel had asked me whether we wanted to be among the companies that offer something special to club members. We are always up for such opportunities. Those who joined the club during the WMF were given a blank. And then they could mint it into a club medal at our booth.”

Club Member Albert M. Beck

Albert M. Beck, founder and honorary president of the World Money Fair, was obviously the first member of the World Money Fair Club. And he also made use of his privilege to mint his own club medal. Markus Schlein comments: “Of course, it was a great honour for us when Albert Beck came to our booth to mint his medal. He told us that minting something himself was not something that happened often in his life. So we were able to teach him a little about it. And not just him, but many new members of the World Money Fair Club. We minted for two hours each on Friday and Saturday.”

The OMP – the downstroking medal press. These gigantic machines are used, for instance, to mint large 1-kilo gold and silver coins. Image: Sack & Kiesselbach.

A Successful Fair for Sack & Kiesselbach

Why does Sack & Kiesselbach invest so much time and money into presenting their company at the World Money Fair? Is it even worth it? Markus Schlein laughed when we asked this question: “Of course it’s worth it! We are a medium-sized company located in the small city of Meerbusch near Düsseldorf, Germany. At the World Money Fair, we get to present our company to the entire world. We know how good, flexible and innovative our oil-hydraulic presses are – and we like to showcase that. We have met countless new customers here. And we obviously also advise customers and sell our presses at our booth. This year, we sold two MPP-250 machines, the very press that we have at our booth. And the Czech precious metal dealer Bessergold ordered an OMP-1250. The OMP is our downstroking medal press. This oil-hydraulic press has a pressing force of up to 1,250 tons – for comparison: a fully-fuelled Boeing 737 weighs around 43 tons. If this press shapes metal, it does so with a force equivalent to the weight of 29 airplanes! Of course, we do not have such a machine ready in stock. All our presses are built after they were ordered, enabling us to take every wish of our customers into account.”

The representatives of Bessergold and the Sack & Kiesselbach raised their glasses to celebrate the successful deal. Image: Sack & Kiesselbach.

A Brief Outlook at 2025

Thus, Sack & Kiesselbach will be back at the World Money Fair in 2025. Markus Schlein has not yet decided what attractions will be presented at their booth in 2025, but he comments: “I’m actually already in the process of developing ideas about what we’ll be showing next time. One thing is certain: we will surprise our visitors again with how flexible our machines are and amaze them with how precise they mint – be it the most beautiful coins, medals, bars or orders.”